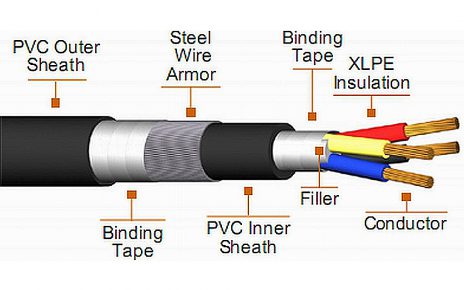

Cables are very diverse depending on the type of application they have and can be found in different forms in the market. The structure and components of telecommunication cables are completely different from the cables used in the high voltage and low voltage electrical industry.. But in general, cables always consist of two main parts: conductor and insulator. The difference between the cables is due to their type of use. That is, their type of application causes the material, shape, number, cross-sectional area of conductors and insulators to differ from each other.. These differences lead to the division of cables.Cable construction

Conductors

Conductors are made of almost pure copper wire with acceptable flexibility or aluminum or special alloys. The cross section of the conductors is made in different sizes and shapes according to the amount of passing current and the type of application. Circular shape of single string with abbreviated symbol (re) and several strings with abbreviations (rm). Triangular (triangle) Single string form with abbreviation (with) and several strings with abbreviations (sm).Cable construction

Insulators

The insulation of the wires and the sheath that is placed on the cable, usually made of PVC plastic (Polyvinyl chloride) Of course, other insulators such as paper and some chemical compounds are used in some special cables. These insulators are based on working and environmental conditions and the type of consumption they have. have the required mechanical strength and electrical characteristics. In order to avoid mistakes and to distinguish the cable wires from each other, the insulation of the conductor wires is chosen in different colors

Cable insulation is made of different types according to the type of application, the most important of which are as follows :

* Oiled paper

* Plastic materials

* PVC (Protodor)

* P.E.T (PE)

Cable sheath

To protect the cables from environmental factors and mechanical shocks, they are covered with one or more layers (casing) Of (Miss, Sarb, Foolad) They cover plastic paper, especially PVC. Cables are divided into different types according to their outer layers.

Allowable current tolerable by the cable

The permissible current passing through the wires and cables is determined in such a way that at any point of the cable, the heat produced in its conductors is well transferred to the surrounding environment; So that the insulation temperature on the conductor surface of PVC wires and cables does not exceed 70 degrees Celsius. The passing current given for electric cables when placed in the soil is based on the cable being placed on a bed of soft sand that is paved with bricks after laying the soil on the surface channel..

In addition, the cable can pass through a limited number of steel pipes, none of which is more than 6 meters long.. The permissible current of the cables that are in the open air is based on the load factor of 1 and in the air with a temperature of 30 degrees Celsius. The permissible current of the cable when it is completely immersed in water is 1.15 times the current in the cable placed in the soil. But it should be noted that when a part of the cable is in the ground or in the open air. These parts determine the current passing through the cable.

Voltage drop in the cable

In electrical energy distribution networks, the size of the cable surface is not only selected based on the permissible current passing through it, but the length of the cable, which is proportional to the voltage drop, is also a determining factor..

Conditions for installing and placing power cables

Cables with insulation and plastic sheath should never be used at temperatures below 5- Celsius installed and cabled. If necessary, the cable reel should be stored in a warm environment around 20 degrees Celsius for a few days before installation. During cabling, the bending radius of plastic cables should not be smaller than 15 times the outer diameter of the cable. But at the end of the cable, the bending radius can be reduced to half of the above value in special cases by following the technical principles.

When the cable is pulled by the machine, care must be taken that the tensile force applied to the cable does not exceed the permissible values. (sieved) placed at a height of 20 cm. Brick on it (And on the brick) Normal soil was poured. This action prevents the pressure of the soil layers on the cable and its shape change, and also prevents the cable from being damaged when digging the ground with a shovel and pickaxe.

A few tips about choosing The right cable

Any cable with a certain cross-sectional area is capable of transmitting a certain current, which if it exceeds that limit, it will shorten the life or burn the cable and cause accidents.. Therefore, in the design of a network, the following three principles must be observed :

* The electric current should not exceed the permissible limit of the cable current.

* The voltage drop should not exceed the permissible limit.

* Economic calculations should be made about the selected cross section in terms of power loss.

Learn more about cables: